| 21 |

Ultra High Purity Pressure Gauges |

GP series pressure gauges are widely used in ultra-high purity gas distribution systems in semiconductor, electronics, medical and other industries. They are suitable for gases, liquids and corrosive media, as well as corrosive environments and high-purity occasions. Dial sizes 50 mm (2 in.), 63 mm (2 1/2 in.), measuring range up to 6000 psi |

|

| 22 |

Canister Assemblies CSR Series |

In the atomic layer deposition (ALD) process, selecting the appropriate precursor is crucial to process control, film performance, etc.; at the same time, according to the characteristics of the precursor, such as volatility, reactivity, etc., matching the appropriate source bottle will have an impact on the process. There is a synergistic effect. The CSR series source bottle components adopt high-quality control from material selection to molding process, so they can be adapted to the packaging and storage of most precursors, providing excellent safety and cleanliness guarantee for the entire deposition process. |

|

| 23 |

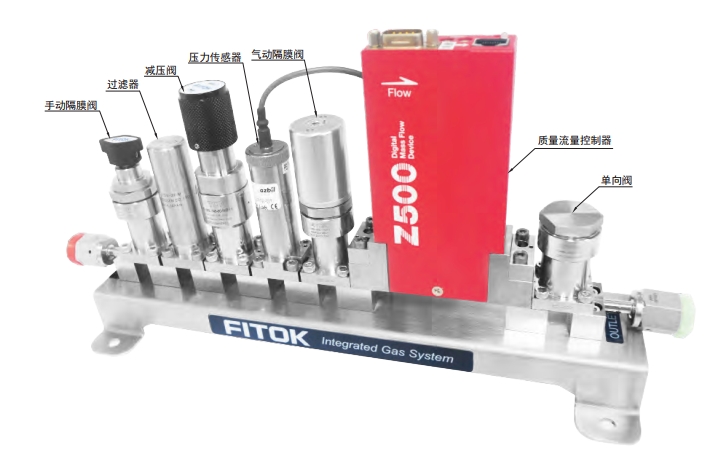

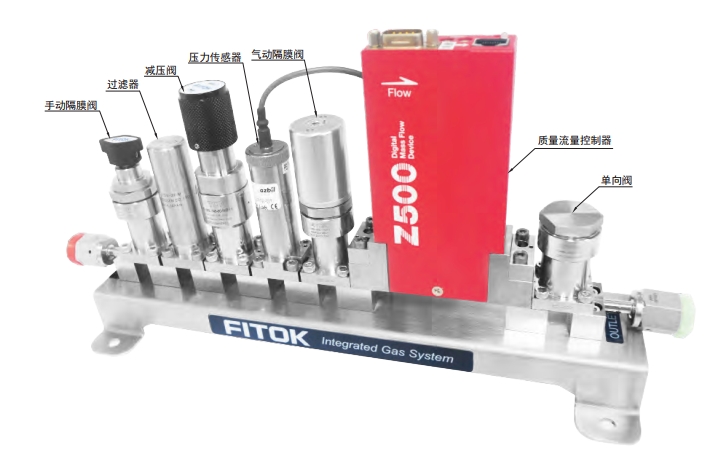

Gas Stick Assemblies |

AGH series high-purity gas control components are suitable for high-purity gas fluid systems in semiconductor and other industries. This series of high-purity gas control components is mainly composed of diaphragm valves, pressure reducing valves, pressure gauges and other accessories. By integrating these components, on-site connections are reduced. Feitok strictly requires process specifications in terms of materials, welding and cleaning to ensure that the products meet the high cleanliness and high performance requirements of the semiconductor manufacturing industry for pipe and valve parts. |

|

| 24 |

Leaflet for Integrated Gas System |

FITOK Modular Gas System (Integrated Gas System) is a device used for gas control in the semiconductor industry. As semiconductor manufacturing technology becomes more and more advanced, the requirements for gas control equipment are also getting higher and higher. The modular gas system adopts surface-mounted components that comply with SEMI standards and carries out modular design. While reducing the size of the equipment, installation and maintenance become simpler. |

|

| 25 |

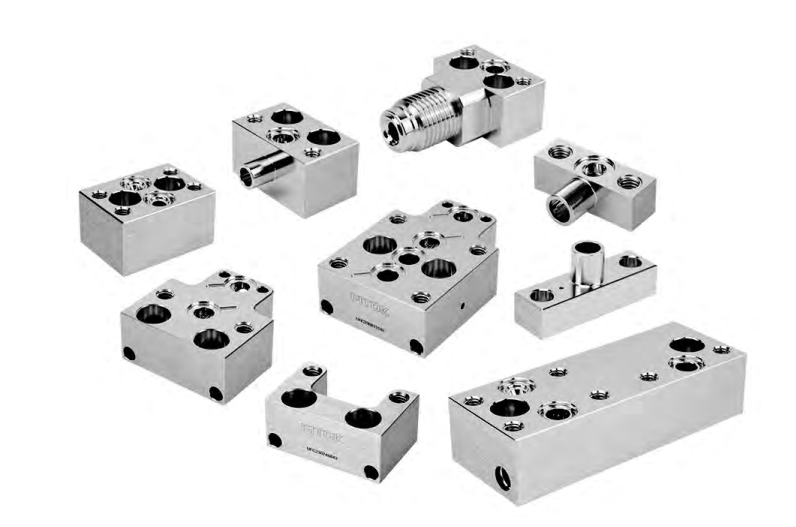

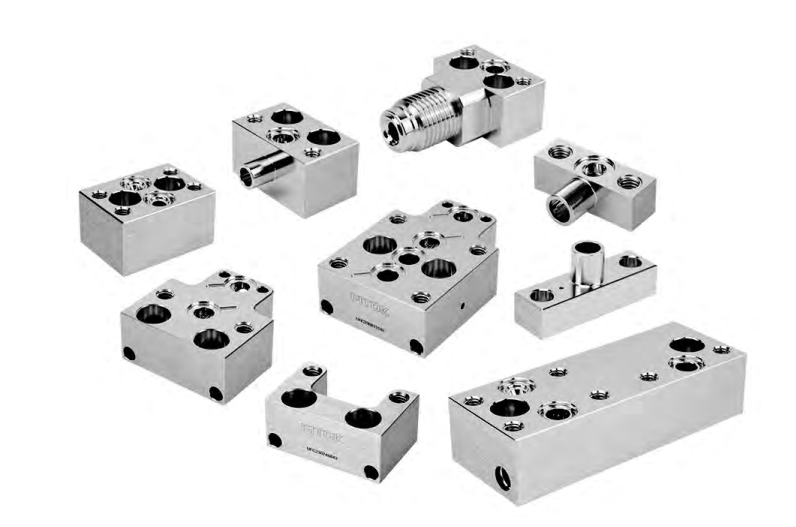

Integrated Gas System Substrates ISC and ISW Series |

The materials comply with SEMI F20 standards, and a variety of flow channel forms are suitable for various modular system construction needs. Final assembly and packaging are completed in an ISO Class 4 clean room. |

|